¶ Introduction

¶ Purpose, Objective and Scope

The objective of this DDF is to present the plumbing system of the Firehorn propellant filling station

¶ Definitions and Abbreviations

- PFS : propellant filling station

- ETH : 90% ethanol

- LOX : liquid oxygen

- N2 : Nitrogen

¶ Applicable and Reference Documents

¶ Requirements

¶ Filling Station

-

2024_C_SE_GS_FILLING-STATION_REQ_01 Declaration of purpose 1

The Filling Station shall be able to remotely fill the LV with fuel. -

2024_C_SE_GS_FILLING-STATION_REQ_02 Declaration of purpose 2

The Filling Station shall be able to remotely fill the LV with oxidizer. -

2024_C_SE_GS_FILLING-STATION_REQ_03 Declaration of purpose 3

The Filling Station shall be able to remotely fill the LV pressurant gas. -

2024_C_SE_GS_FILLING-STATION_REQ_17 Fluid compatibility 1

The GSE shall be compatible with gaseous nitrogen pressurized at [400]bars. -

2024_C_SE_GS_FILLING-STATION_REQ_18 Fluid compatibility 2

The GSE shall be compatible with liquid ethanol pressurized at [5]bars. -

2024_C_SE_GS_FILLING-STATION_REQ_19 Fluid compatibility 3

The GSE shall be compatible with liquid oxygen pressurized at [15]bars. -

2024_C_SE_GS_FILLING-STATION_REQ_04 Emergency manual disconnect

The Filling Station shall feature a clearly marked and labelled, single action, hand actuated, emergency release mechanism. -

2024_C_SE_GS_FILLING-STATION_REQ_05 Oxidizer filling disconnect

The Filling Station shall be able to disconnect the filling hose remotely. -

2024_C_SE_GS_FILLING-STATION_REQ_06 Power Supply to LV

The Filling Station shall be able to power the LV while it is on the pad with [24]V DC. -

2024_C_SE_GS_FILLING-STATION_REQ_07 Telemetry link

The Filling Station shall receive its commands via a telemetry link with the GS. -

2024_C_SE_GS_FILLING-STATION_REQ_10 Propellant loading and pressurization time

The filling/loading/unloading of the liquid fuels shall take maximum [45] minutes, including pressurization. -

2024_C_SE_GS_FILLING-STATION_REQ_12 Safing and arming distance

All ground-started propulsion system ignition circuits/sequences shall not be "armed" until all personnel are at least [15] m away from the launch vehicle. -

2024_C_SE_GS_FILLING-STATION_REQ_13 Propellant offloading after launch abort

The GSE shall implement a means for remotely controlled venting or offloading of all liquid and gaseous propellants in the event of a launch abort. -

2024_C_SE_GS_FILLING-STATION_REQ_14 Dissimilar loading lines

All loading lines shall feature dissimilar connectors. -

2024_C_SE_GS_FILLING-STATION_REQ_15 Contact between fluids

The GSE shall prevent detrimental contact between dissimilar fluids. -

2024_C_SE_GS_FILLING-STATION_REQ_16 Pollution

Disconnection between the GSE and the LV shan't cause pollution to the launch site. -

2024_C_SE_GS_FILLING-STATION_REQ_20 Electrical connection

The GSE shall be able to charge the rocket with with [24]V and [1]A current. -

2024_C_SE_GS_FILLING-STATION_REQ_21 Operations human needs

The arming of the Filling Station on the LV shall require at most [2] operators. -

2024_C_SE_GS_FILLING-STATION_REQ_22 Arming time

The arming of the Filling Station on the LV shall require no more than [5]min. -

2024_C_SE_GS_FILLING-STATION_REQ_23 Reusability

The Filling Station should be fully reusable after nominal LV launches and vertical static fires.

¶ Functional Description

The propellant filling station is used to remotely fill the rocket with LOX, ETH and nitrogen prior to launch. It also actuates the quick disconnect arms and Thermal insulation.

¶ Physical Diagram

|

|

|---|---|

|

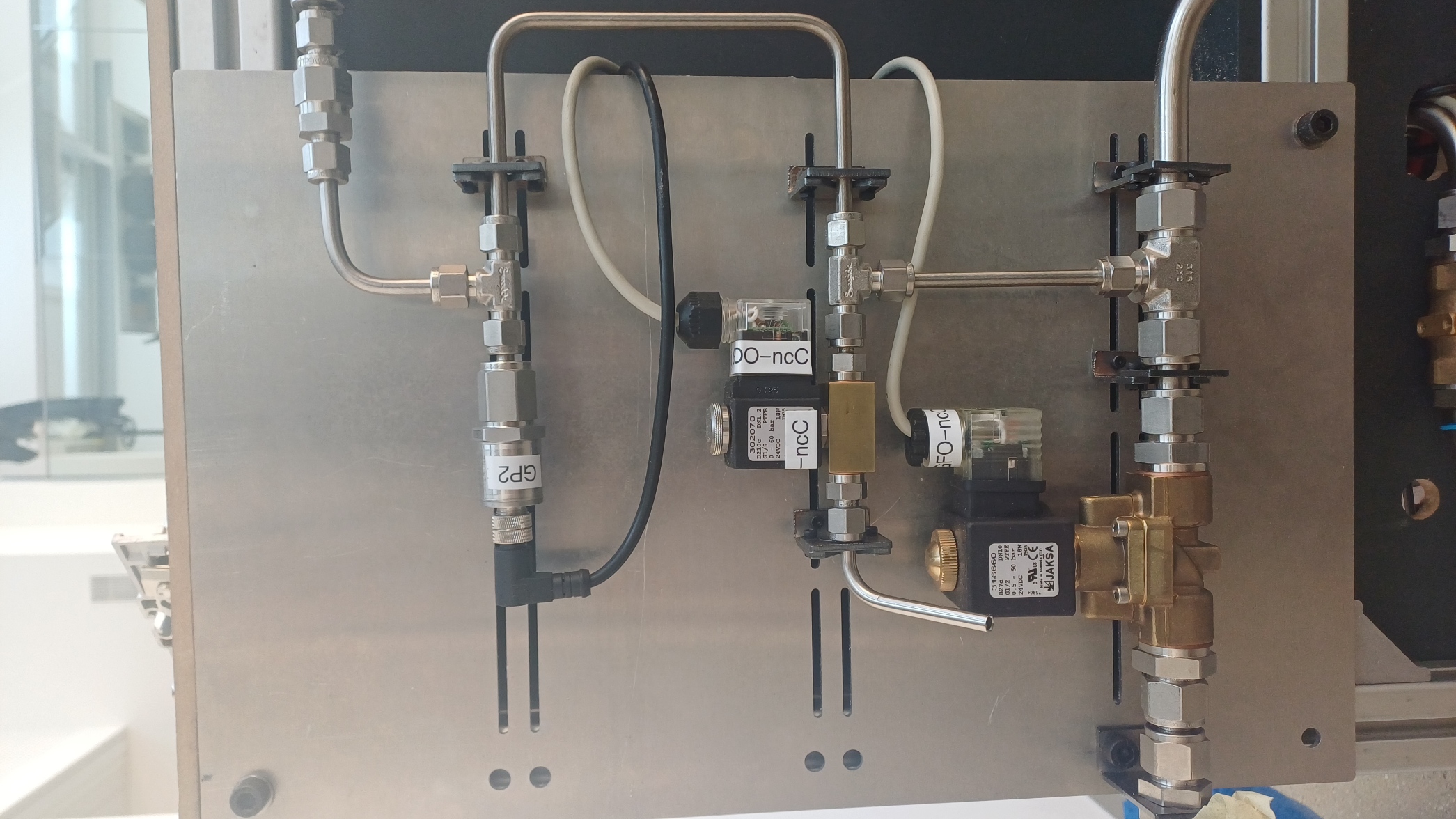

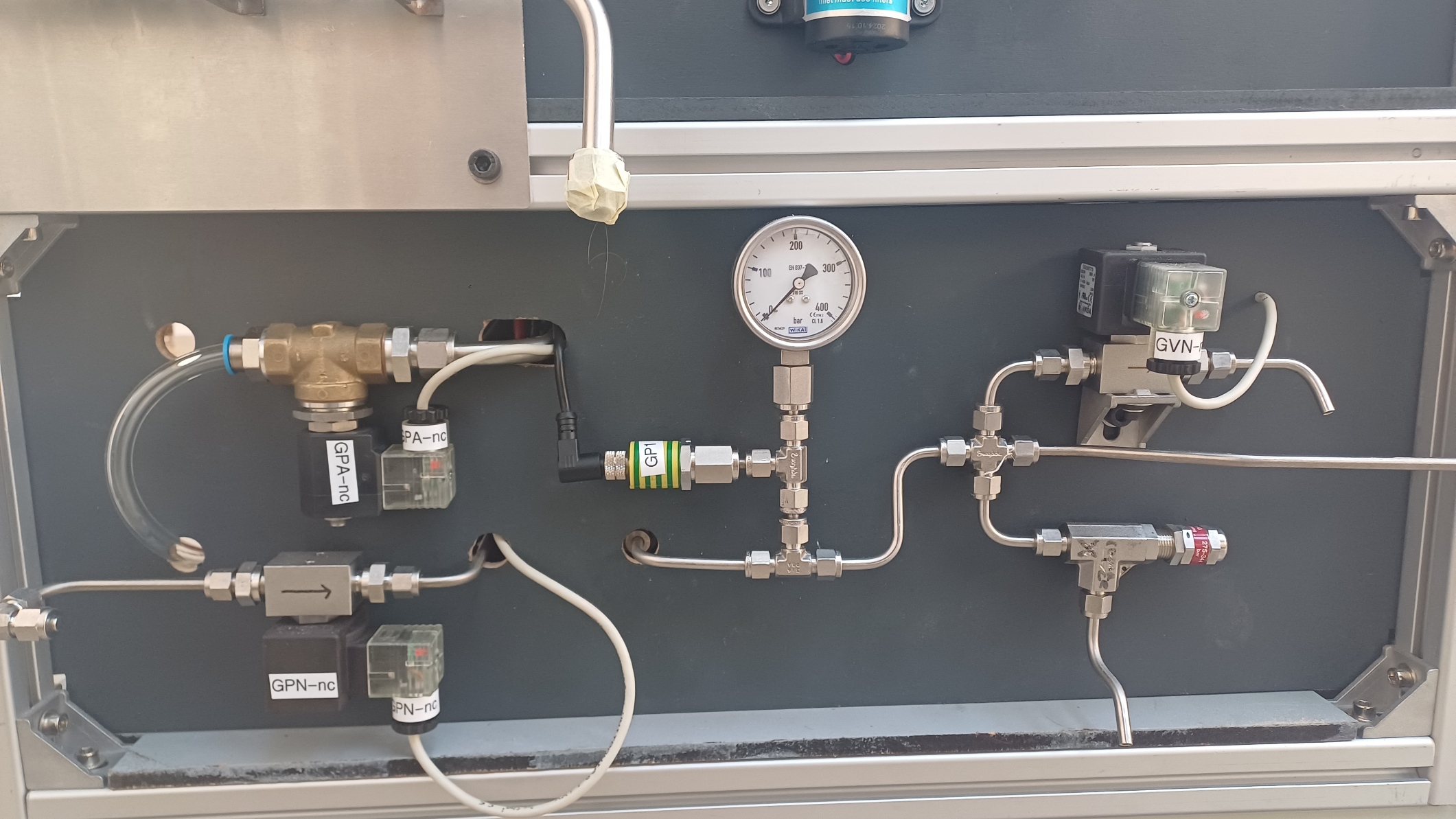

¶ Plumbing

¶ Diagram

¶ Part list

¶ Nomenclature

The valves are named with a unique code to differentiate them explicitely. While the complete code of the valves contains some precise informations about it, only the first 2 letters can be used without ambiguity in OP or orally during testing or operation (only for active valves). The naming scheme is described below. The letter G is added at the begining here to signify that those valves are on ground. This is done in order not to mix them up with flight valves that uses the same nomenclature.

¶ Active valve

| Function | Fluid | Valve type | Cryo (if applicable) |

| :---------: | :---------: |:---------: |

| F:Filling, V:Vent, M:Main, D: Drain, P: Pressurisation, L: Line purge, I:Igniter, Q: Quick disconnect| O:Oxydizer, E:Ethanol, N:nitrogen, A:Air | NC (Normally Close) , NO (Normally Open) or NA (Non Applicable)| C or nothing |

¶ Passive valve

| Passive | Valve type| Fluid| Line function | Cryo (if applicable) |

| :---------: | :---------: |:---------: |

|P|C: check valve, R: relief, B burst disk | O:Oxydizer, E:Ethanol, N:nitrogen | F:Filling, V:Vent, M:Main, D: Drain, P: Pressurisation, L: Line purge, I:Igniter | C or nothing |

¶ Sensors

| Name | Use | link |

|---|---|---|

| GP1 | Nitrogen pressure in the filling line | 400 bars sensata |

| GP2 | LOX pressure in the deware | 100 bars sensata |

| GP3 | Pressure of the compressors | 100 bars sensata |

| GP4 | Nitrogen input pressure | 400 bars sensata |

¶ Valves

¶ Other

| Name | Use | link |

|---|---|---|

| Compressors | Drive the gas booster | https://www.arebos.ch/ch_de/spezielle-kategorien/luftkompressor-1200w-6l.html?gad_source=1&gclid=Cj0KCQjwm7q-BhDRARIsACD6-fV7Y_XgwV2STs2_ZVz8ACIghpb8in42L9RDvfCGhxBiuaZ5tSd6_XwaAgr0EALw_wcB |

| Gas booster | Boost nitrogen pressure up to 480 bars | https://usun1988.en.made-in-china.com/product/OsUxulwYnKVt/China-Usun-Model-Us-GB-Single-Action-Air-Driven-Gas-Booster-System-with-Valves-Gauges-and-Pressure-Regulators.html |

| Pressure regulators | Carbagas output up to 16 bar pressure regulator | TBC, already in stock |

| Pump | Pump ethanol in the rocket | https://fr.aliexpress.com/item/32456615586.html?spm=a2g0o.order_list.order_list_main.208.33235e5bFIs0N0&gatewayAdapt=glo2fra |